Johnson 9.9 Service Manual Free

The 9.9 is ok. I would like to go bigger but with the restrictions in NJ it wouldn't make sense. Also I fish my hometown Lake (Lenape) which if you go over 10hp you need 500,000 boaters liability insurance. It does get on plane I just had to adjust pitch of motor alittle.Search OutBoard Service Repair manuals up top and you will see a post from Jim (site Admin). He has downloadable manuals in PDF format. You will need to download dropbox to receive them. I do believe you need to be an active member and have at least 25 posts though.

I did get mine through him.Tom. Congrats,Great and dependable motors. (would definitely get service manual for your baby) It will help provide good running, long life, and help you do your own maintenance and definitely save you money!!Use 50:1 gas/oil ratio (TCW-3 2cycle oil only) Mix oil and gas together because this is the motor only source of lubrication!!! Many of people who purchase an outboard do not realize this and burn a motor up!!8oz oil with 3gallons of gas16oz oil with 6gallons of gasLinks to find and purchase a service manual for your motor.There are online Johnson/Evinrude parts list and diagrams.

1968 to present.(good link here)(type in year, make and model of your Johnson)Good links for information about your motor!(great link for your motor and up keep and maintenance)Happy boating my friend!!cajuncook1. Repair-guidebook merchants are proud to offer Outboard service repair manuals for your Johnson Evinrude – download your manual now!Factory manual in pdf format covering most Johnson Outboard factory Service manual 1956-2010.1956 1957 1958 1959 1960 1961 1962 1963 1964 1965 1966 1967 1968 1969 1970 1971 1972 1973 1974 1975 1976 1977 1978 1979 1980 1981 1982 1983 1984 1985 1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010.Complete list of Johnson Evinrude outboard service repair manuals.

JohnsonEvinrude 1990-2001 service manual.pdf - Free ebook download as PDF File. For a mechanical engine, particularly an outboard motor, to be left sitting idle. From 1990 to 2001 Johnson and Evinrude produced a large number of. Search by model number, brand, year and horsepower to find the service manual/operators guide that fits your exact Evinrude or Johnson outboard motor. Here is a FREE manual for a Johnson or Evinrude outboard motor. If you have a Johnson or Evinrude outboard this is the repair manual. Normally you would have to pay some scum on ebay or somewhere for this, but we could care less.

The Johnson-Evinrude Workshop manual downloads for the above listed models describes the service procedures for the complete vehicle. Follow the Maintenance Schedule recommendations to ensure that the outboard is in peak operating condition.

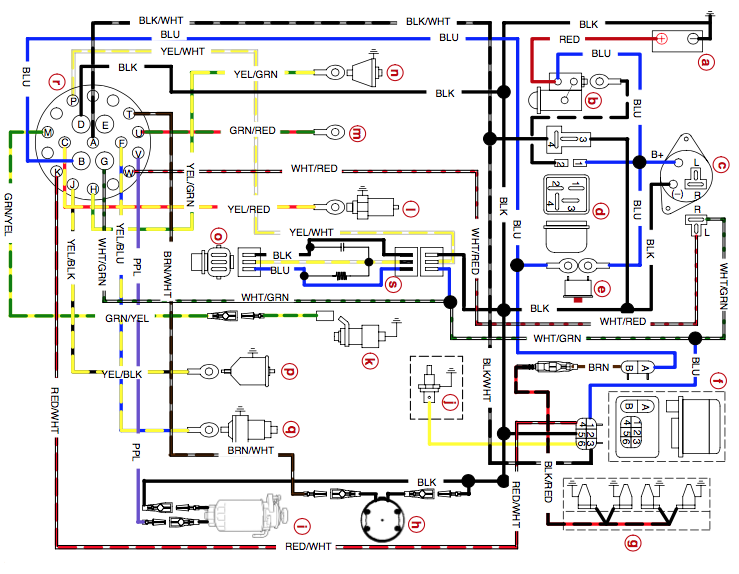

Performing the scheduled maintenance is very important. It compensates for the initial wear that occurs during the life of the outboard motor.All chapters in the Workshop Manual apply to the whole vehicle and illustrates procedures for removal/installation of components that are in detailed step-by-step fashion.Most all Workshop manual chapters start with an assembly or system illustration, diagrams, exploded parts view, pictures, service information and troubleshooting for the section. The subsequent pages give detailed procedures. You can compare the major components of an outboard with the engineand drivetrain of your car or truck.

In doing so, the powerhead is theequivalent of the engine and the gearcase is the equivalent of your drivetrain(thethe power necessary to move the'vehicle, while the gearcask is thkassembly that transmits that power via gears, shafts and a propeller (insteadof tires).Speaking in this manner, the powerhead is the 'engine' or 'motor' portionof your outboard. It is an assembly of long-life components that are protectedthrough proper maintenance. Lubrication, the use of high-quality oils (2-stroke or 4-stroke) and proper fuelioil ratios (2-stroke) or frequent oilinspectionlchanges (4-stroke) are the most important ways to preservepowerhead condition. Similarly, proper tune-ups that help maintain properairlfuel mixture ratios and prevent pinging, knocking or other potentiallydamaging operating conditions are the next best way to preserve your motor.But, even given the best of conditions, components in a motor begin wearingthe first time the motor is started and will continue to do so over the life ofthe powerhead.Eventually, all powerheads will require some repair.

The particular brokenor worn component, plus the age and overall condition of the motor may helpdictate whether a small repair or major overhaul is warranted. The complexityof the job will vary with 2 major factors. As much as you can generalizeabout mechanical work:transmissionltransaxle T. He powerhead is the assemblv that produces.the more difficult the repairThe larger and more complex the motor, the more difficult the repair.Again, these are generalizations and, working carefully, a skilled do-ityourselfboater can disassemble and repair aas a seasoned professional. But both DlYers and professionals must knowtheir limits. These days, many professionals will leave portions of machinework (from cylinder block and piston disassembly, clean and inspection tohoning and assembly up to a machinist). This is not because they are notcapable of the task, but because that's what a machinist does day in and dayout.

A machinist is naturally going to be more experienced with theprocedures.If a complete powerhead overhaul is necessary on your outboard, werecommend that you find a local machine shop that has both an excellentreputation and that specializes in marine work. This is just as important andhandv a resource to the rofessionaal s a DIYer. If ossiblec. Onsult with themachke shop before disassembly to make sure you follow procedures ormark components, as they would desire. Some machine shops would preferto perform the disassembly themselves. In these cases, you can usuallyremove the powerhead from the gearcase and deliver the entire unit to theshop for disassembly, inspection, machining and assembly.If you decide to perform the entire overhaul yourself, proceed slowly,taking care to following instructions closely.

Consider using a digital camera(if available) to help document assemblies during the removal anddisassembly procedures. This can be especially helpful if the overhaul orrebuild is going to take place over an extended amount of time. If this is yourfirst overhaul, don't even THINK about trying to get it done in one weekend,YOU WON'T. It is better to proceed slowly, asking help when necessary fromyour trusted parts counterman or a tech with experience on these motors.Keep in mind that anytime pistons, rings and bearings have beenreplaced, the powerhead must be broken-in again, as if it were a brand-newmotor. Once a major overhaul is completed, refer to the section onPowerhead Break-In for details on how to ensure the rings set properlywithout damage or scoring to the new cylinder wall or the piston surfaces.Careful break-in or a properly overhauled motor will ensure many years ofservice for the trusty powerhead. The age of the motor (the older OR less well maintained the motor is) 70 hp EFI powerhead, as well.

Evinrude Etec 60 Hp Service Manual Pdf

+ See Figure 1The gearcase is considered that part of the outboard below themidsectioniexhaust housing. The gearcase contains the propeller shaft, thedriven and pinion gears, the driveshaft from the powerhead and the waterpump. On models equipped with shifting capabilities, the fonvard and reversegears, together with the clutch, shift assembly, and related linkage, are allhoused within the case.The single most important task for proper gearcase maintenance isinspecting it for signs of leakage after each use.

If oil can get out, then watercan get in. And, water, mixing with or replacing the oil in the gearcase willwreak havoc with the shafts and gears contained within the housinq.The second most important task for proper gearcase maintenance ischeckinq and maintainina the oil inside the case. Not onlv is it imortanttomake sire the oil is at t k proper level (not above or below), but it isimportant to check the oil for signs of contamination from moisture. Waterentering the gearcase will usually cause the oil to turn a slightly milky-whitecolor.

Also, significant amounts of water mixed with the oil will give theappearance of an overfilled condition.If you suspect water in the gearcase, start by draining and closelyinspecting the fluid (refer to the procedures found in the Maintenance andTune-Up section). Then, refill the unit with fresh oil and test the outboard (byusing it!). Watch the fluid level closely after the test, and for the first fewoutings.

If any oil leaks out or water enters, either the propeller shaft sealmust be replaced or the gearcase must be disassembled, inspected andcompletely overhauled. To be honest, a complete overhaul is recommended,because corrosion and damage may have occurred if moisture was in thegearcase long enough. But, in some cases, if the leak was caught in time,and there is no significant wear, damage or corrosion in the gearcase, thepropeller shaft seal can usually be replaced with the gearcase still installedto the outboard.The last, most important task you can perform to help keep your gearcasein top shape, is to flush the inside and outside of the aearcase after eachuse.' inseth e outside of the unit with a hose to remove any sea life, salt,chemicals or other corrosion inducing substances that you may have pickedup in the water. Cleaning the gearcase will also help you spot potentialFig.maximum efficiency, compared with a unit receiving TLC (tenderloving care) 1 A neglected lower unit cannot be expected to perform totrouble, such as gearcase oil leaks, cracks or damage that may haveoccurred during use.

Remove any sand, silt or dirt that could potentiallydamage seals or clog passages. Once you've rinsed the outside, hook up aflushing device and do the same for the inside.

Shivam vijay tv serial. Aug 11, 2017 Shivam Vijay Tv Serial Full episode Videos dvd cassette sale Rs 600. Vijay Tv Serials Shivam full Videos Dvd Sales. DVDs Available, HD Quality 9 DVDs Rs 650,. Shivam is a Tamil mythological serial, telecasted in Star Vijay channel. Shivam is a dubbed version of Hindi serial Devon Ke Dev Mahadev aired at life ok. Shivam - Vijay TV serial is with Srinivas Chowdary.

Again, details are found inthe Maintenance and Tune-up section, look under Flushing the CoolingSystem.REMOVAL & INSTALLATIONThe most common reason for removrng and installing the gearcaseperform service (inspect or replace) the water pump impeller. On all motorsexcept the 2.0-3.5 hp (78cc) motors, the water pump is found on the IS togearcase-to-midsectionhousing) split line. On 2.0-3.5 hp (78cc) motors the pump is mounted just infront of the propeller, so the gearcase does not have to be removed on thesesmall motors in order to service the pump.Removal and installation roceduresa re rovidedh ere for each of thegearcases used on these &nson/vinrude'motorsE. Xploded views are alsoprovided, in case disassembly and overhaul are required. (sometimes known as the intermediate or exhaustColtiJunior (43cc) Motors + See Figures 2 and 31.

For safety, disconnect the spark plug lead, then ground it to thecylinder head.2. If necessary for service or access, remove the propeller, for detailsrefer to the procedure in the Maintenance and Tune-Up section.3.

Remove the two screws securing the lower unit to the exhausthousing.4. Taking Care not to damage the driveshaft and the water tube,separate the lower unit from the exhaust housing by pulling straightdownward.5.gearcase.6. Thoroughly inspect the gearcase and exhaust housing for signs ofdamage. Make sure all mating surfaces are clean and free of debris,corrosion or damage. If necessary for service or overhaul, drain the gear oil from theTo install:7. Apply a light coating of OMC Moly Lube, or equivalent assemblylubricant to the driveshaft splines.

Be sure to coat only the SIDES of thesplines and not the top of the shaft, as that could hydraulically prevent thedriveshaft from fully seating in the crankshaft spline.8. Apply a light coat of clean liquid soap to the water tube grommet.9. Apply a light coating of OMC Nut Lock, or equivalent threadlock tothe threads of the 2 gearcase mounting screws.10.

Install the gearcase, while carefully aligning the water tube in thearommet and the driveshaft slinesto the crankshaft shaft. If necessarv, turn?he propeller shaft slowly clockwise (when viewed from the shaft end) ioalign the splines.